Si-TPV 3100-55A Exceptional Aesthetics thermoplastic silicone-based elastomers

Tsananguro

SILIKE Si-TPV imhando yeSilicone-based thermoplastic yakagadzirwa ne thermoplastic yakagadzirwa ne silicone-based elastomers, iyo yakagadzirwa ne tekinoroji inoenderana nayo, inobatsira silicone rabha kupararira muTPU zvakaenzana semadonhwe e 2 ~ 3 micron pasi pe microscope. Izvi zvinhu zvakasiyana zvinopa musanganiswa wakanaka wehunhu uye mabhenefiti kubva ku thermoplastics uye silicone rabha yakabatana zvizere. Inokodzera pamusoro pechinhu chinopfekwa, Bhomba refoni, zvishandiso zvemagetsi (earbuds, semuenzaniso), overmolding, dehwe rekugadzira, Automotive, high-end TPE, TPU industries ....

Mashoko

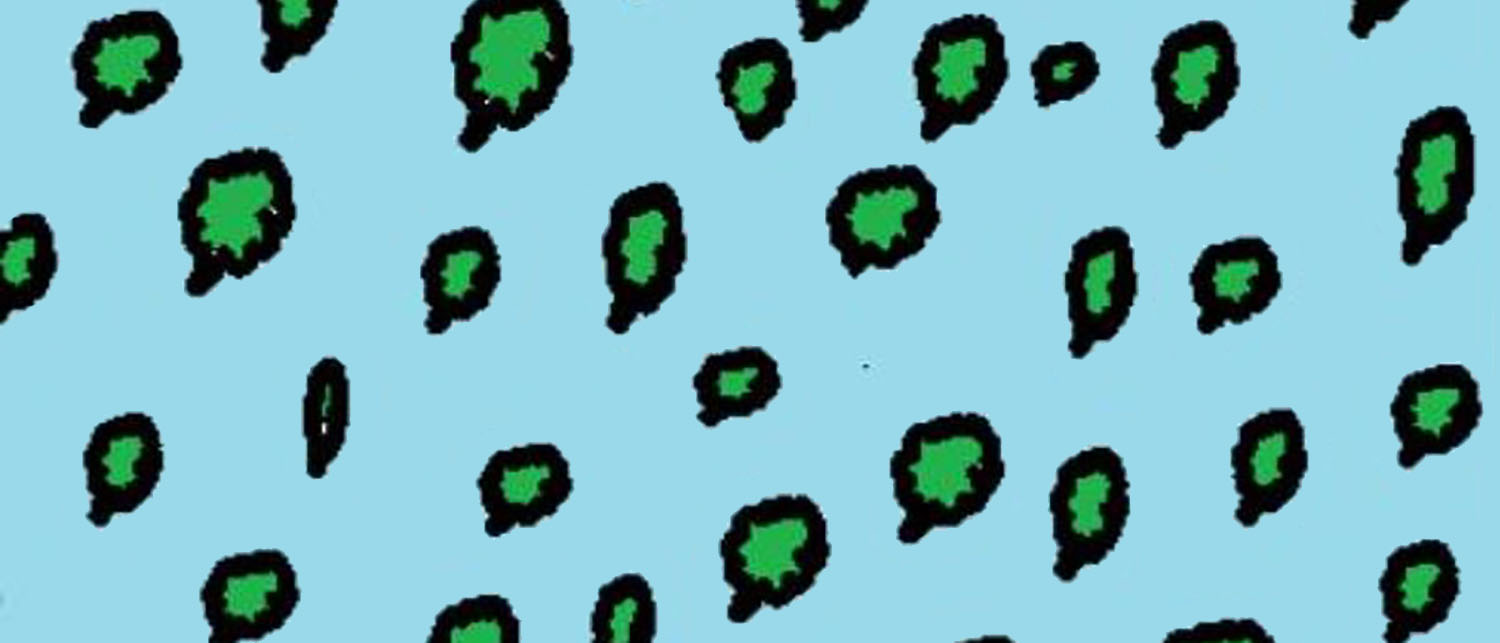

Chikamu chebhuruu ndicho chikamu chekuyerera kwemvura (flow phase TPU), icho chinopa hunhu hwakanaka hwemakanika.

Chikamu chegirini chine silicone raber particles chinopa ganda rakasimba, rinodzivisa kupisa kwakanyanya uye kwakaderera, rinodzivisa mamiriro ekunze, rinodzivisa mavara, nezvimwewo.

Chikamu chitema chinhu chakakosha chinoenderana nacho, chinovandudza kuenderana kweTPU nerabha resilicone, chinosanganisa hunhu hwakanaka hwezvinhu zviviri izvi, uye chinokunda zvikanganiso zvechinhu chimwe chete.

3100 dzakatevedzana

| Chinhu chekuyedza | 3100-55A | 3100-65A | 3100-75A | 3100-85A |

| Modulus yeElasticity (MPa) | 1.79 | 2.91 | 5.64 | 7.31 |

| Kureba panguva yekutyoka (%) | 571 | 757 | 395 | 398 |

| Simba rekusimba (Mpa) | 4.56 | 10.20 | 9.4 | 11.0 |

| Kuoma (Shongwe A) | 53 | 63 | 78 | 83 |

| Kuwanda (g/cm3) | 1.19 | 1.17 | 1.18 | 1.18 |

| MI(190)℃,10KG) | 58 | 47 | 18 | 27 |

3300 series -- Inorwisa mabhakitiriya

| Chinhu chekuyedza | 3300-65A | 3300-75A | 3300-85A |

| Modulus yeElasticity (MPa) | 3.84 | 6.17 | 7.34 |

| Kureba panguva yekutyoka (%) | 515 | 334 | 386 |

| Simba rekusimba (Mpa) | 9.19 | 8.20 | 10.82 |

| Kuoma (Shongwe A) | 65 | 77 | 81 |

| Kuwanda (g/cm3) | 120 | 1.22 | 1.22 |

| MI(190)℃,10KG) | 37 | 19 | 29 |

Mako: Data iri pamusoro apa rinoshandiswa chete sechiratidzo chechigadzirwa chakajairika, kwete sechiratidzo chehunyanzvi

Mabhenefiti

1. Ita kuti pamusoro payo pave nekubata kwakasarudzika uye kwakasununguka paganda, kunyorova nemaoko uye hunhu hwakanaka hwemuchina.

2. Haina plasticizer nemafuta anonyorovesa, haina njodzi yekubuda ropa/kunamira, haina hwema.

3. Kudzivirira UV kwakasimba uye makemikari ane hukama hwakanaka neTPU nezvimwe zvakafanana ne polar substrates.

4. Deredza kunyudzwa kweguruva, kusapindirana nemafuta uye kuderedza kusvibiswa.

5. Zviri nyore kushandisa, uye zviri nyore kubata

6. Kuramba kwenguva refu kwekukuvara & kuramba kupwanyika

7. Kuchinjika kwakanaka uye kuramba kusingadzoreki

Mashandisirwo

1. Kugadzira jekiseni zvakananga

2. Sanganisa SILIKE Si-TPV® 3100-65A neTPU pamwero wakati, wobva waisa mvura kana kuibaya.

3. Inogona kugadziriswa maererano nemamiriro ekugadzirisa TPU, kurudzira kuti tembiricha yekugadzirisa ive 160~180 ℃

Mashoko

1. Mamiriro ekushanda anogona kusiyana zvichienderana nemidziyo nemaitiro ega ega.

2. Kuomesa kwese kunokurudzirwa kushandisa desiccant inobvisa hunyoro

Chidzidzo chekushandisa chakajairika

Zvakanakira zvebhande repachifukidziro rakagadzirwa neSi-TPV 3100-65A:

1. Kubata ganda zvine silika, zvine hushamwari, masutu evana zvakare

2. Kushanda kwakanaka kwazvo kwe encapsultaion

3. Kushanda zvakanaka pakudhaya

4. Kushanda zvakanaka pakuburitsa uye zviri nyore kugadzirisa

Pasuru

25KG / bhegi, bhegi repepa rehunyanzvi rine bhegi remukati rePE

Nguva yekuchengetedza zvinhu uye kuchengetwa kwazvo

Tungamirwa semakemikari asina njodzi. Chengeta munzvimbo inotonhorera, ine mhepo inofefetera zvakanaka.

Hunhu hwepakutanga hunoramba hwakafanana kwemwedzi gumi nemiviri kubva pazuva rekugadzirwa, kana hukachengetwa munzvimbo inorayirwa.

ZVIMWE ZVESILICONE ZVEMAHARA UYE MIFANANIDZO YESI-TPV ZVINOPFUURA MAGREYI 100

Rudzi rwemuenzaniso

$0

- 50+

mamakisi Silicone Masterbatch

- 10+

mamakisi eSilicone Powder

- 10+

mamakisi Anti-kukwenya Masterbatch

- 10+

mamakisi Anti-abrasion Masterbatch

- 10+

mamakisi Si-TPV

- 8+

mamakisi eSilicone Wakisi

-

Runhare

-

E-mail

-

WhatsApp

WhatsApp

-

Pamusoro

- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur